Product description:

Automatic 5gallon Barrel Filling bottling packing Machine for 20L 18.9L 19L

Barreled water producing line is the core equipment in the 5 Gallon barreled drinking water producing line. It is the ideal equipment for mineral water, distilled water and purified water producing process. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance. The main electrical parts adopt products with brand of Siemens and OMRON. Pneumatic parts adopt products with brand of AIRTAC. Both the inner and outer shower nozzle for washing barrel adopt the special technology equipment from American sprayer company. The machine works reliably and efficiently based on the compact structure and high automatic technology. It is the fully automatic barreled water producing equipment combined with machine, electronic and pneumatic components.

Advantage:

The whole machine is made of stainless steel.

2.This filling line specially produces 3&5 gallons barreled drinking water.

3.This series barreled filling production line integrates bottle washer, filler and sealer into one unit.

4.In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. The sealer can seal bottle caps automatically.

5. This filling line equips with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy.

6. This line also can automatically carry out bottle washing, sterilizing, filling, capping, counting and products discharging.

7. It has features of complete functional, novel design, and high degree of automation. It is a new kind of barreled water auto-producing line, which integrates mechanism, electricity and pneumatics technologies together.

8. It meets the demands of food hygiene. Its structure is reasonable and its operation is convenient.

9. It is ideal equipment for producing mineral water, super-pure water, space water and distilled water.

10. Its key parts are imported and their quality is reliable.

11. It is suitable for filling of all kinds of round and square barrels.

12. The production line adopts electric-program control. It has safe devices, such as interlock, signal, automatic check and so on.

5 gallon 3gallon and 5gallon Technical parameter:

2400BPH 5Gallon filling machine

1)filling technics and structure is designed and innovated by ourselves. It adopts large fluent filling and fix quantify filling . filling valve is SUS fine casting process, it has airproof ring to avoid attrition of the metal .it is control by cylinder , and it is stabilization . in the filling process, barrel after washing transport to covey barrel screw. The covey barrel screw apart the barrel equality to star-wheel. The star-wheel lead the barrel to filling system. When the filling cylinder meet journey switch, cylinder moves down to open filling valve. Filling valve start to fill. After filling , cylinder meet with journey switch again and move up. Filling valve close. The barrel after filling export by star-wheel. And transport to capping machine by chains.

Filling parts has 18 filling valves to satisfy the speed of the machine . at the same time , liquid position is nicety because of controlling by journey switch.

capping machine adopts SUS chains continuum capping

Automatic cap loader machine

clearance form cap loader . control by PLC

step-less

Flexible strap

power :0.18kw

transport chains system

Chain design and make fine, out shape is beautiful. Chain and chain are connected in reason. it is suitable for barrel transporting .the height of feeding barrel chain is 700mm. the height of outing barrel chain is 600mm,it is convenient for light inspect. chain panel adopts high quality project plastic panel. chain side panel and shield fence adopt SUS304.drive motor reducer adopt joint venture products chain goes calm. it is easy to install and maintenance .it has long life.

Light inspect

Frame out shield adopts SUS304. It is brightness beautiful and easy to operate with good effects .

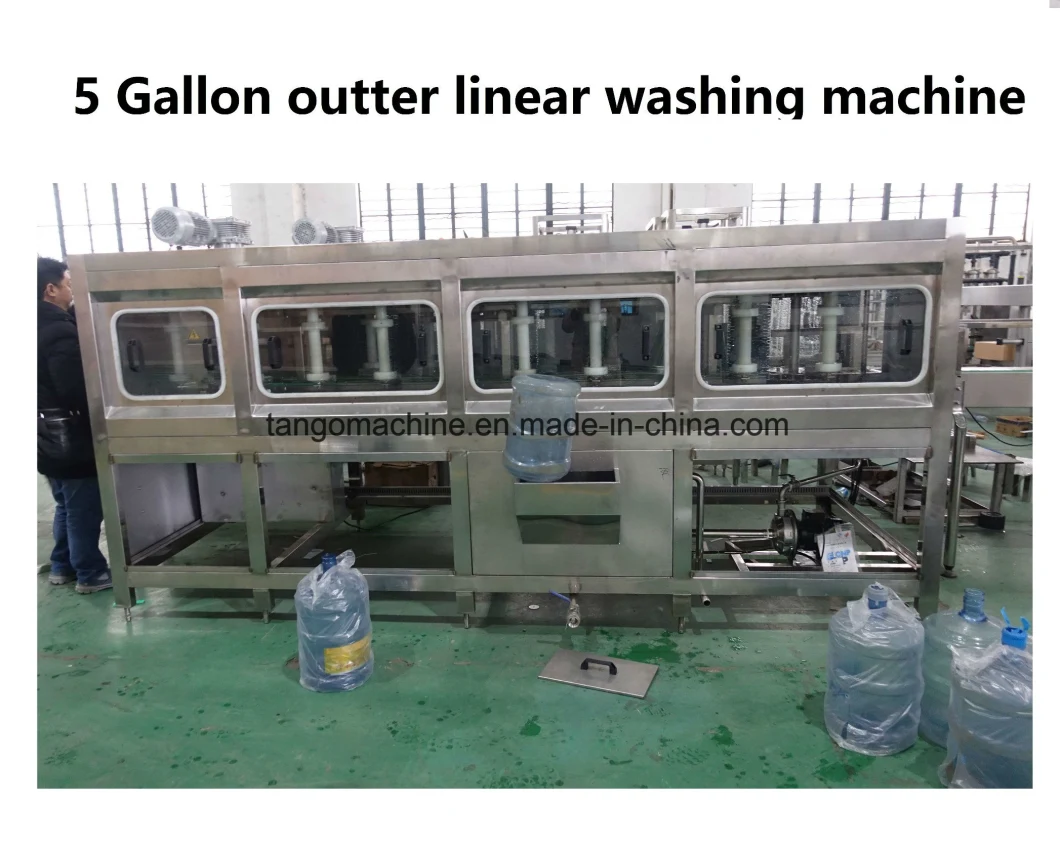

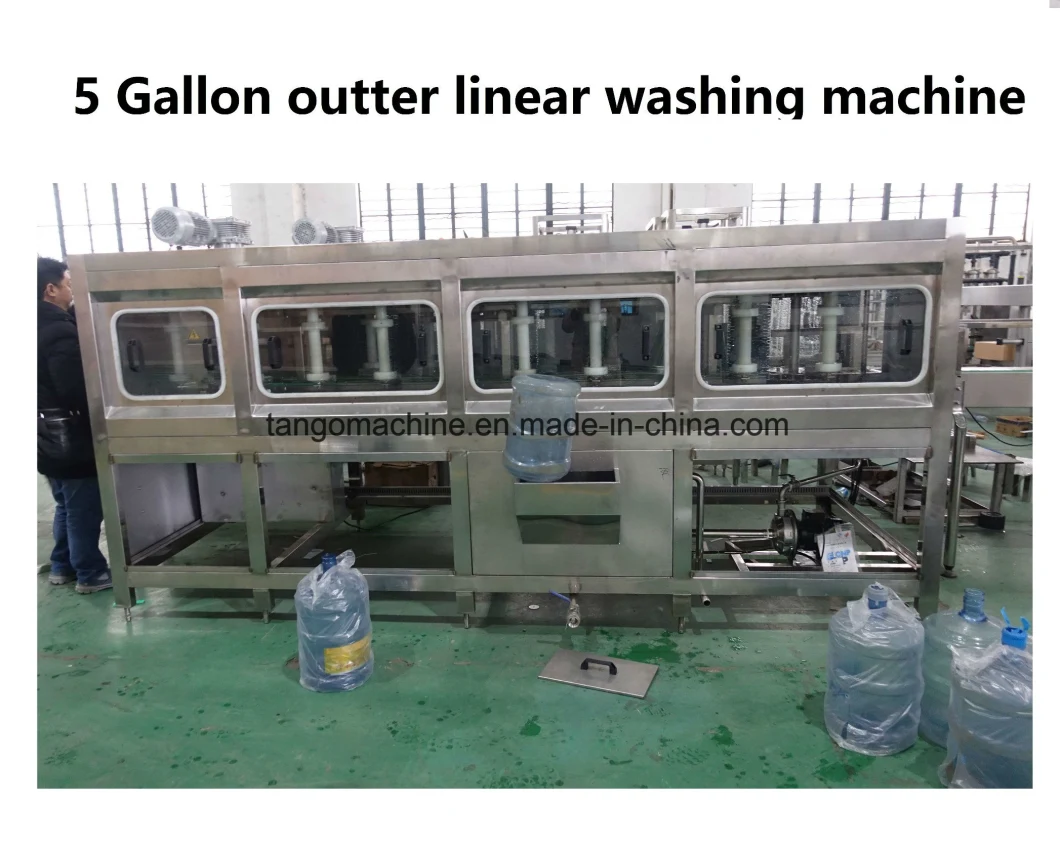

outside barrel brushing machine

This machine is designed and create by ourselves.5 gallon barrel and hair brusher are contact and movement to get perfect brushing effects. It is able to wash barrel of neck ,body ,bottom and so on .it matched with circle water pump, two layers sieve net , organic glass cover.

After sale service

1. Welcome to consult us for offer and technical solution:

2. free design workshop layout as workshop space.

3. free check raw material quality report to match suit water treatment system.

4. Engineer install and train client how to use and maintain machine

5. one year guarantee

6. if some client urgently need machine, we can ship machine half month under supply caps and bottle samples to meet with client quick need.

some basic details need buyer support:

1. bottle and cap samples

2. workshop space length and width size

3. source water quality report

4. capacity requirement, we will match solution as it.

5. and other details need check

Automatic 5gallon Barrel Filling bottling packing Machine for 20L 18.9L 19L

Barreled water producing line is the core equipment in the 5 Gallon barreled drinking water producing line. It is the ideal equipment for mineral water, distilled water and purified water producing process. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance. The main electrical parts adopt products with brand of Siemens and OMRON. Pneumatic parts adopt products with brand of AIRTAC. Both the inner and outer shower nozzle for washing barrel adopt the special technology equipment from American sprayer company. The machine works reliably and efficiently based on the compact structure and high automatic technology. It is the fully automatic barreled water producing equipment combined with machine, electronic and pneumatic components.

| Machine | Model | QGF-120 | QGF-240 | QGF-300 | QGF-400 | QGF-600 |

| Capacity (b/h) | 120 | 240 | 360 | 480 | 600 | |

| Filling head | 1 | 2 | 3 | 4 | 5 | |

| Overall size (mm) | 3700*1600*1800 | 4000*1500*1800 | 4000*1580*1800 | 4000*1580*1800 | 5000*1850*1900 | |

| Power | Main machine (kw) | 3.8 | 6.8 | 8.8 | 11 | 11 |

| Heating(kw) | 9 | 10 | 12 | 12 | ||

| Compressed air | Air pressure | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Air consumption | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | |

| Lye | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

| Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

| Circle water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

| Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

| Sterilizing water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

| Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

| Pure water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

| Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

| Pure water rinsing consumption | 600 | 1000 | 1500 | 2000 | 2500 | |

Advantage:

The whole machine is made of stainless steel.

2.This filling line specially produces 3&5 gallons barreled drinking water.

3.This series barreled filling production line integrates bottle washer, filler and sealer into one unit.

4.In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. The sealer can seal bottle caps automatically.

5. This filling line equips with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy.

6. This line also can automatically carry out bottle washing, sterilizing, filling, capping, counting and products discharging.

7. It has features of complete functional, novel design, and high degree of automation. It is a new kind of barreled water auto-producing line, which integrates mechanism, electricity and pneumatics technologies together.

8. It meets the demands of food hygiene. Its structure is reasonable and its operation is convenient.

9. It is ideal equipment for producing mineral water, super-pure water, space water and distilled water.

10. Its key parts are imported and their quality is reliable.

11. It is suitable for filling of all kinds of round and square barrels.

12. The production line adopts electric-program control. It has safe devices, such as interlock, signal, automatic check and so on.

5 gallon 3gallon and 5gallon Technical parameter:

| Type | QGF-100 | QGF-240 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Filling heads | 1 | 2 | 3 | 4 | 8 | 8 | 8 |

| Barrel size(mm) | 276*490 | ||||||

| Capacity(b/h) | 60-100 | 100-240 | 250-300 | 400 | 800 | 800 | 800 |

| Gas pressure(MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.6 | 0.6 | 0.6 |

| Gas consumption(m3/min) | 0.37 | 0.37 | 0.6 | 0.8 | 1 | 1.5 | 1.8 |

| Motor power (kw) | 1.38 | 1.75 | 3.8 | 3.8 | 7.5 | 9.75 | 13.5 |

| Rated voltage | 380V/50HZ | ||||||

| Weight (kg) | 680 | 800 | 1500 | 2100 | 3000 | 3500 | 4500 |

2400BPH 5Gallon filling machine

1)filling technics and structure is designed and innovated by ourselves. It adopts large fluent filling and fix quantify filling . filling valve is SUS fine casting process, it has airproof ring to avoid attrition of the metal .it is control by cylinder , and it is stabilization . in the filling process, barrel after washing transport to covey barrel screw. The covey barrel screw apart the barrel equality to star-wheel. The star-wheel lead the barrel to filling system. When the filling cylinder meet journey switch, cylinder moves down to open filling valve. Filling valve start to fill. After filling , cylinder meet with journey switch again and move up. Filling valve close. The barrel after filling export by star-wheel. And transport to capping machine by chains.

Filling parts has 18 filling valves to satisfy the speed of the machine . at the same time , liquid position is nicety because of controlling by journey switch.

capping machine adopts SUS chains continuum capping

Automatic cap loader machine

clearance form cap loader . control by PLC

step-less

Flexible strap

power :0.18kw

transport chains system

Chain design and make fine, out shape is beautiful. Chain and chain are connected in reason. it is suitable for barrel transporting .the height of feeding barrel chain is 700mm. the height of outing barrel chain is 600mm,it is convenient for light inspect. chain panel adopts high quality project plastic panel. chain side panel and shield fence adopt SUS304.drive motor reducer adopt joint venture products chain goes calm. it is easy to install and maintenance .it has long life.

Light inspect

Frame out shield adopts SUS304. It is brightness beautiful and easy to operate with good effects .

outside barrel brushing machine

This machine is designed and create by ourselves.5 gallon barrel and hair brusher are contact and movement to get perfect brushing effects. It is able to wash barrel of neck ,body ,bottom and so on .it matched with circle water pump, two layers sieve net , organic glass cover.

After sale service

1. Welcome to consult us for offer and technical solution:

2. free design workshop layout as workshop space.

3. free check raw material quality report to match suit water treatment system.

4. Engineer install and train client how to use and maintain machine

5. one year guarantee

6. if some client urgently need machine, we can ship machine half month under supply caps and bottle samples to meet with client quick need.

some basic details need buyer support:

1. bottle and cap samples

2. workshop space length and width size

3. source water quality report

4. capacity requirement, we will match solution as it.

5. and other details need check