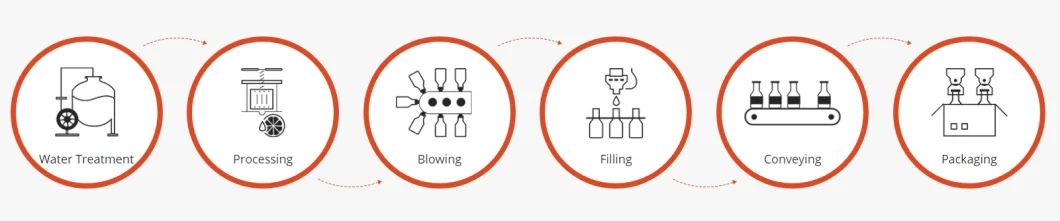

The carbonated drinking filling machine could be separated to 3 modules. The height of the bottle-out conveyor is adjustable. Bottles are conveyed to rinser, filler and capper through starwheel and conveyed out finally through bottle-out conveyor. Equip with alarm device for bottle block, bottle absence, cap absence and overload. The machine meets the national food hygienic standard, with high automation and easy to operate. (Carbonated Beverage Bottling Filling machine)

| Model(RFC-C) | 14-12-5 | 16-16-5 | 24-24-8 | 32-32-8 | 40-40-10 | 50-50-12 | 60-60-15 |

| Capacity(BPH) | 3000 | 5000 | 8000 | 12000 | 15000 | 18000 | 20000 |

| Suitable to Bottle Shape | Round and Square container Bottle diameter: 50-120mm Bottle Height: 160-320mm | ||||||

| Drive Motor | 2.42 | 3.12 | 3.92 | 3.92 | 5.87 | 7.87 | 11.37 |

| Rinsing water pump power(KW) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Rinsing Time(s) | 4.2 | 2.8 | 3.1 | 3 | 2.8 | 2.8 | 2.8 |

| Drain Time(s) | 2.3 | 1.6 | 1.8 | 2.5 | 1.6 | 1.6 | 1.6 |

| Compressed air consumption(m³/min) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Water Consumption(T/H) | 1.5 | 1.5 | 2 | 2 | 3 | 3 | 3 |

| CO2consumption (m³/min) | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 |

| Dimension(L*W*H)mm | 2360*1770*2700 | 2760*2060*2700 | 2800*2230*2700 | 3550*2650*2700 | 4700*3320*2700 | 5900*4150*2700 | 5770*5290*2700 |

Main Features(Carbonated Beverage Bottling Filling machine)

2.High speed filling line adopts bottle gripper conveying technology. It is free to change over bottle size and the working table inside the machine is more laconic.

3.By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier.

4.Specially designed stainless steel bottle gripper dose not contact the thread parts of the bottle neck, avoiding the second contamination.

5.Pressure liquid carousel. High speed line adopts annular liquid carousel.

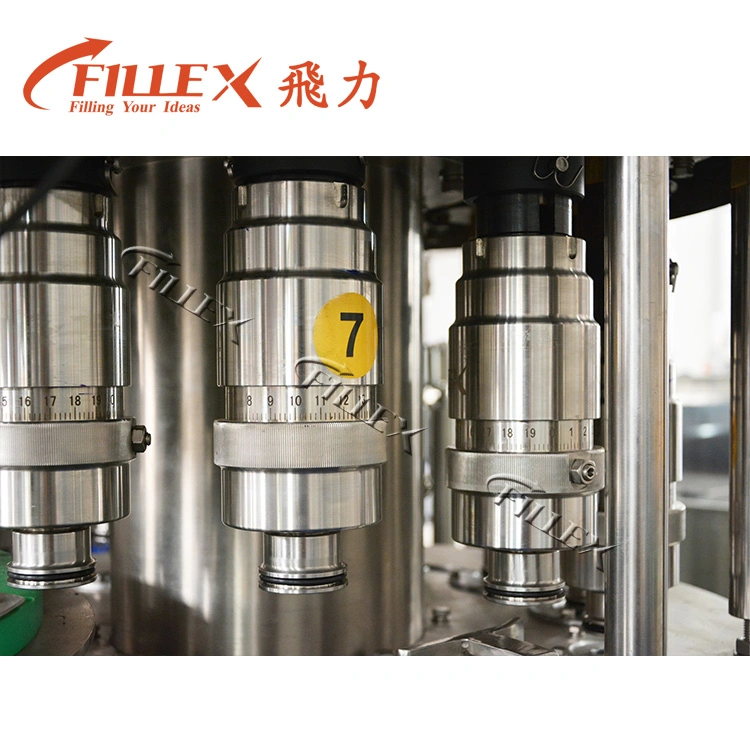

6.High speed and mass flow filling valve ensures the high filling speed and exact fluid level.

7.Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic. The electric system is from international brand and achieves the national food hygienic standard.

8.The bottle-out starwheel is helical structure. While changing over bottle size, it is no need to adjust bottle-out conveyor height.

Fillex Team

One-stop Solution

Customer Service

More than 60 exporting countries, serving more than 180 customers, such as Thailand, Myanmar, Russia, South Africa, Turkey, Argentina, USA, Canada, Mexico, Australia, etc.

We already have 3 branches: Indonesia, Dubai, Saudi Arabia.

1 year quality warranty and supply spare parts at low cost for life span after sale. We keep the original

drawings of spare parts, so it can match with the rest part of machine.

2. 24 hours/365 days online technical service.

3. Training offered

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.