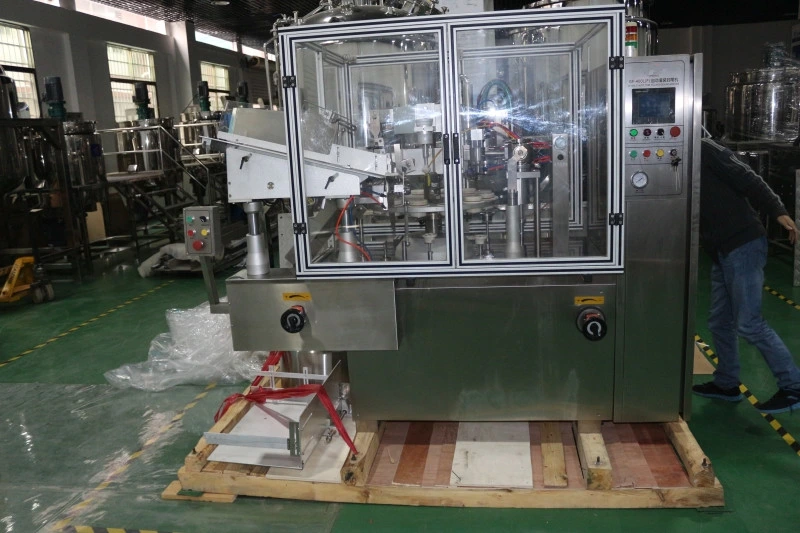

Automatic tube filling and sealing machine is designed for plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc. industries. Its operating principle is to put the pipes which is in the feeder hopper into the first service position filling model individually, to invert with rotating disk, to test nomenclature plate in pipe when inverting to the second , to fill with nitrogen gas into pipe in the third, to fill with desired substance in the fourth, then to fix the heating, folding, jamming, number printing, cooling, slivers trimming etc service position, to export the finished products when inverting to the last service position so the twelfth. Every pipe should take such series process to filling, sealing to completion.

- Tube orientation checking, Heating and cutting.

- This tube filling and sealing machine is suitable for operating filling, sealing a quantity of viscosity of oil, cream and gel ointment, etc.

- Accuracy filling, balanced action, low buzz.

- Automatically Tube Filling Machine Manufacture finished overall process as tube supply, photoelectron register, inert gases filling (optional), material filling and sealing, batch number printing, finished products output.

- Adjust position outlay and position numbers video picture, quickly and accurately adjustment ( suitable for varies specification and varies product producing )

- Mechanical, photoelectron, electric, pneumatic integrative controlling, reaches no tube no filling function; warning if tube error positioned or pressure too low, automatic stop machine if open the protective door.

| Machine name: | Tube filling and sealing machine |

| Filling product: | Cream/ointment/lotion/paste/semi-liquid product |

| Filling volume: | 10-300ml |

| Capacity: | 1800-4000Pcs/Hr |

| Tube material: | Plastic tube, Multiple tube |

| Filling nozzle: | Leakage-proof |

| Tube diameter | φ13-φ60 mm |

| Tube length: | 50-250mm(customizable) |

| Working accuracy: | ±1% |

| Air pressure: | 0.4-0.8Mpa |

| Electric voltage: | AC220V/380V 50HZ 3Phase |

| Machine dimension: | 2620*1250*1980mm L*W*H |

| Net Weight: | 1100kg |

1) Provide 24-hour service hotline for tube filling and sealing machine.

2) Reply and find out solution within the shortest time according to customer's requirement.

3) Provide on call service to help customer solve problems.

4) Provide free of machine installation as well as commissioning, and inform customer how to do the machine maintenance.

5) Prepare customer's feedback tracking within one week after machine installation until meet customer's satisfaction.

6) Provide one year guaranty and lifetime maintenance.

1. Q: How is the after sales service?

A:We provide 1 year tube filling and sealing machine guaranty and technical support lifetime for Tube filling and sealing machine. All machine's parts can be replaced for free within 1 year if broken (excluding error operation).

2. Q: Is it difficult to install the machine?

A: The work shop should prepare full facility such as power and air compressor. For the first installation, engineer will be sent to set machine and do the machine training as long as manual instruction. For the further problems come out, we can provide video instruction as well.

3. Q: What's the tube filling and sealing machine lead time?

A: For the standard machines, we can delivery within 15 days. If it is customized by customer(OEM), the lead time is 30-45 days.